Turning Center TCK-58L

TCK-58H series turning center, the overall bed is made of high-quality Meehanite cast iron, and vibration is eliminated, suitable for long-term heavy-duty operation. In addition, the bed channel is induction hardened and precision ground to achieve straightness accuracy. The bed is also designed with three "V" shapes and a flat staircase to improve machining reliability and precision.

Product use

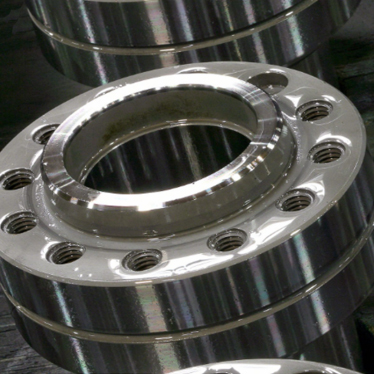

Turning centers are widely used in the processing of precision shaft parts

Turning center, widely used in the processing of threaded parts

The turning center is suitable for the processing of precision connecting rod parts

Turning center, widely used in the processing of hydraulic pipe joint parts

Turning centers are widely used in the processing of precision shaft parts

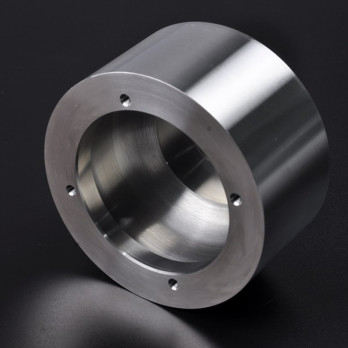

Precision components

Machine tool configuration Taiwan Yintai C3 high-precision guide rail

Machine tool configuration Taiwan Shangyin high-precision P-grade screw rod

All spindles are extremely robust and thermally stable

The machine tool offers a wide range of chip removal and cooling systems

Machine offers a wide range of tooling options and quick-change tool holders

Configure brand CNC system

TAJANETurning centers machine tools, according to customer needs, provide various brands of CNC systems to meet customers' different needs for vertical machining centers, FANUC, SIEMENS, MITSUBISH, SYNTEC, 。

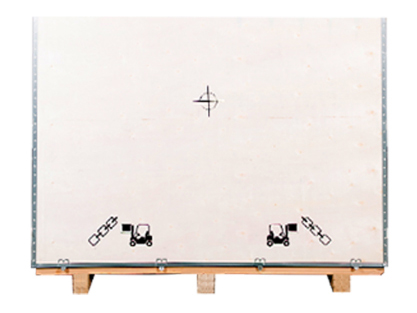

Fully enclosed packaging, escort for transportation

Fully enclosed wooden packaging

Turning Center TCK-58L, fully enclosed package, escort for transportation

Vacuum packaging in the box

Turning Center TCK-58L, with moisture-proof vacuum packaging inside the box, suitable for long-distance long-distance transportation

Clear mark

Turning Center TCK-58L, with clear markings in the packing box, loading and unloading icons, model weight and size, and high recognition

Solid wood bottom bracket

Turning Center TCK-58L, the bottom of the packing box is made of solid wood, which is hard and non-slip, and fastens to lock the goods

| Part | Model Item | RH-25HA-750MY | RH-25HA-1000MY | RH-25HA-2000MY | RH-25HA-3000MY |

| The main parameters | The maximum upper rotation diameter of the bed surface | Φ920 | |||

| Maximum machining diameter | Φ600 | ||||

| The maximum processing diameter on the tool post | Φ600 | ||||

| Maximum processing length | 590 | 890 | 2040 | 2980 | |

| Spindle and chuck parameters | Spindle head form | A2-11 | A2-11 | A2-11 | A2-11 |

| Optional chuck(special configuration) | 12”(15”) | 12”(15”) | 12”(15”) | 12”(15”) | |

| Recommended spindle motor power | 1800 rpm | 1800 rpm | 1800 rpm | 1800 rpm | |

| Spindle speed | 22-30KW | ||||

| Spindle hole diameter | Φ102 | Φ102 | Φ102 | Φ102 | |

| Bar diameter | Φ91 | Φ88 | Φ88 | Φ88 | |

| Feed section parameters | X/Z/Y axis screw specifications | 4008/5010 | |||

| X/Z/Y axis rail specifications | Hard track | ||||

| X/Z//Y axis limit travel | 330/940/120(±60) | 330/1240/120(±60) | 330/2440/120(±60) | 330/3340/120(±60) | |

| Recommended X/Z/Y axis motor torque | 22 N.M/22 N.M/15N.M | ||||

| X/Z/Y axis connection method | Direct connection/direct connection/synchronous wheel | ||||

| Turret or Row | Optional turret(special configuration) | Sanwa SHD25BR-380(Cheng Tong BMT65-380-V12) | |||

| Power head specification | BMT65/ER32 | ||||

| Power head speed | 5000rpm | ||||

| Transmission ratio of power shaft and tool seat | 1:1 | ||||

| Recommended turret center height dimension | 125 | ||||

| Tailstock | Socket diameter | 100 | |||

| Socket travel | 80 | ||||

| Tailstock maximum stroke | 785 | 1085 | 2285 | 3185 | |

| Tailstock sleeve tapered hole | Mohs 5# | ||||

| Appearance | Dimensions (length x width x height) | Integral/30°/2940/1503/1950 | Integral/30°/3240/1503/1950 | Integral/30°/4440/1503/1950 | Integral/30°/5340/1503/1950 |

Standard Configuration

● High-quality resin sand casting, HT250, the height of the main shaft assembly and tailstock assembly is 60mm;

● Imported screw (THK);

● Imported ball rail (THK or Yintai);

● Spindle assembly: the spindle is Luoyi or Taida spindle assembly;

● Main motor pulley and belt;

● Screw bearing: FAG;

● Joint venture lubrication system (River Valley);

● Black, according to the color palette provided by the customer, the paint color can be configured;

● Encoder assembly (without encoder);

● One X/Z shaft coupling (R+M);

● Braking system.