In the field of modern industrial manufacturing, the vertical machining centre is a crucial equipment. It provides strong support for the processing of various workpieces with its unique performance and wide application.

I. Main functions of vertical machining centre

Milling function

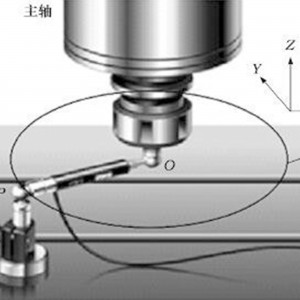

The vertical machining centre can excellently complete the tasks of milling planes, grooves and surfaces, and can also process complex cavities and bumps. Through the milling tool installed on the spindle, under the precise control of the machining program, it cooperates with the workpiece workbench moving in the direction of the three coordinate axes of X, Y and Z to achieve accurate shaping of the workpiece to meet the standard required by the drawing.

Point control function

Its point control function is mainly aimed at the hole processing of the workpiece, covering a variety of hole processing operations such as centre drilling positioning, drilling, reaming, streaming, hining and boring, providing an efficient solution for the hole processing of the workpiece.

Continuous control function

With the help of linear interpolation, arc interpolation or complex curve interpolation movement, the vertical machining centre can mill and process the plane and curved surfaces of the workpiece to realise the processing needs of complex shapes.

Tool radius compensation function

This function is of great significance. If you program directly according to the contour line of the workpiece, the actual contour will be a larger tool radius value when machining the inner contour, and a smaller tool radius value when machining the outer contour. Through tool radius compensation, the numerical control system automatically calculates the centre trajectory of the tool, which deviates from the tool radius value of the workpiece contour, so as to accurately process the contour that meets the requirements. Moreover, this function can also compensate for tool wear and machining errors to realise the transition from rough machining to finishing.

Tool length compensation function

Changing the length compensation amount of the tool can not only compensate for the length deviation value of the tool after the tool is changed, but also regulate the plane position of the cutting process to effectively control the axial positioning accuracy of the tool.

Fixed cycle processing function

The application of fixed cycle processing instructions greatly simplifies the processing program, reduces the workload of programming, and improves the processing efficiency.

Subprogram function

For parts with the same or similar shape, it is written as a subroutine and called by the main program, which can greatly simplify the program structure. This modularization of the program is divided into different modules according to the process of the processing process and written into a subprogram, and then called by the main program to complete the workpiece processing, which makes the program easy to process and debugging, and is also conducive to optimising the processing process.

Special function

By configuring copying software and copying device, scanning and data collection of physical objects in combination with sensors, NC programs are automatically generated after data processing to realise the copying and reverse processing of workpieces. After configuring certain software and hardware, the use function of the vertical machining centre has been further expanded.

II. Processing scope of vertical machining centre

Surface processing

Including milling of horizontal plane (XY), positive plane (XZ) and side plane (YZ) of the workpiece. You only need to use a two-axis and half-controlled vertical machining centre to complete the milling tasks of these planes.

Surface processing

For the milling of complex curved surfaces, a three-axis or even more shaft-linked vertical machining centre is needed to meet higher machining accuracy and shape requirements.

III. Equipment of vertical machining centre

Holder

The universal fixture mainly includes flat-mouth pliers, magnetic suction cups and press plate devices. For medium, large quantities or complex workpieces, combination fixtures need to be designed. If pneumatic and hydraulic fixtures are used and automatic loading and unloading are realised through program control, it will significantly improve work efficiency and reduce labour intensity.

Cutter

Commonly used milling tools include end milling cutters, end milling cutters, forming milling cutters and hole machining tools. The selection and use of these tools need to be determined according to specific machining tasks and workpiece materials to ensure processing quality and efficiency.

IV. Advantages of vertical machining centre

High-precision

It can realise high-precision processing and ensure that the size and shape accuracy of the workpiece meet the strict requirements.

High stability

The structure is strong and stable, which can maintain good performance during long-term operation and adapt to various complex processing environments.

Strong flexibility

A variety of different types of processing operations can be carried out to meet the changes of different workpieces and production needs.

Simple operation

After a certain training, the operator can master its operation methods and improve production efficiency.

Good versatility

Work with other equipment to improve the efficiency and coordination of the overall production system.

Cost-effective

Although the initial investment may be high, its efficient processing and low maintenance costs make it more cost-effective in long-term use.

V. Application field of vertical machining centre

Aerospace

It is used to manufacture complex aerospace components, such as engine blades, body structures, etc.

Automobile manufacturing

Production of key components such as engines and transmissions of cars, as well as body moulds, etc.

Mechanical manufacturing

Process all kinds of mechanical parts, such as gears, shafts, etc.

Electronic equipment

Manufacturing electronic equipment shells, internal structural parts, etc.

Medical devices

Produce high-precision medical device parts.

In a word, as one of the important equipment in modern industry, the vertical machining centre plays an irreplaceable role in various fields with its diversified functions, wide processing range, sophisticated equipment and many advantages. With the continuous progress of science and technology and the continuous change of industrial demand, the vertical machining centre will continue to develop and improve, injecting new vitality and impetus into the development of the manufacturing industry.

In the future, we can expect the vertical machining centre to make greater breakthroughs in intelligence and automation. Through the combination of advanced sensor technology, artificial intelligence and big data, a more intelligent processing process monitoring and optimisation is achieved. At the same time, with the development of material science, the research and development of new tools and fixtures will further improve the processing performance and efficiency of vertical machining centres. In addition, under the general trend of green manufacturing, vertical machining centres will also develop in the direction of more energy-saving and environmental protection to meet the requirements of sustainable development.

Millingmachine@tajane.com This is my email address. If you need it, you can email me. I’m waiting for your letter in China.