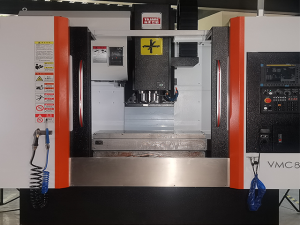

As an indispensable and important equipment in modern industrial production, CNC milling machine has a vital impact on the efficiency and quality of production. In order to ensure that the CNC milling machine can work steadily for a long time, the correct maintenance method is essential. Let’s discuss the maintenance points of CNC milling machines in depth with CNC milling machine manufacturers.

I. Maintenance of numerical control system

The CNC system is the core part of the CNC milling machine, and its strict maintenance is very important. First of all, it should be carried out in strict accordance with the operation and maintenance rules of the numerical control system to ensure the normal operation of the heat dissipation and ventilation system of the electrical cabinet. Poor heat dissipation and ventilation may cause the system to overheat, thus affecting the stability and life of the system.

At the same time, it is necessary to minimise the operation of unnecessary input and output devices and maintain and inspect them regularly. The brush of DC motor and brushless DC motor will gradually wear out during use. When the wear transition, it must be replaced in time, otherwise it will affect the performance of the motor and even cause damage to the motor. For CNC lathes, CNC milling machines, machining centres and other equipment, a comprehensive inspection should be carried out once a year.

For long-term backup printed circuit boards and battery backup circuit boards, they should be replaced regularly and installed in the numerical control system for a period of time to prevent damage. This can keep the circuit board in good condition and ensure that it can work normally when needed.

II. Maintenance of mechanical parts

Adjustment of spindle drive belt

It is very important to regularly adjust the tightness of the spindle drive belt. The loose belt may lead to slipping, affecting the rotation speed and torque transmission of the spindle, and thus affecting the machining accuracy and efficiency. This situation can be prevented by adjusting the tightness of the belt appropriately.

Maintenance of spindle lubrication constant temperature tank

It is necessary to check the constant temperature tank of the spindle lubrication, adjust the temperature range, replenish the oil in time, and clean the filter. Good lubrication and constant temperature control help to maintain the good working condition of the spindle, reduce wear and thermal deformation, and improve processing accuracy.

Attention to the spindle clamping device

After long-term use of the CNC milling machine, the spindle clamping device may have problems such as notches, which will have an impact on tool clamping. Therefore, the displacement of the hydraulic cylinder piston should be adjusted in time to ensure that the tool can be firmly clamped to avoid loosening or falling off during processing.

Maintenance of ball screw thread pairs

Regularly check the status of the ball screw threaded pair and adjust the axial spacing of the threaded pair. This can ensure the accuracy of reverse transmission and axial stiffness, and ensure the accuracy and stability of the machine tool during feed movement. At the same time, it is necessary to regularly check whether the connection between the screw and the bed is loose. If there is any loose, it should be tightened in time. Once the thread protection device is damaged, it should be replaced immediately to prevent dust or chips from entering the threaded pair and causing damage.

III. Maintenance of hydraulic and pneumatic systems

Hydraulic and pneumatic systems also play an important role in CNC milling machines. Regular maintenance of hydraulic and pneumatic systems is essential.

First of all, the filter or filter should be cleaned or replaced to ensure that the oil and gas of the hydraulic and pneumatic systems are clean. Clean oil and gas can reduce impurities and pollutants in the system, and reduce the risk of wear and failure of components.

Secondly, the inspection of conventional oil testing and the replacement of hydraulic oil in the pressure system should be carried out. Hydraulic oil will gradually deteriorate during use and lose its due performance. Regular replacement of hydraulic oil can ensure the normal operation of the hydraulic system and improve the reliability of the system.

In addition, the air filter should be maintained regularly to ensure that the air entering the pneumatic system is clean and dry. At the same time, the accuracy of the machine should be checked and calibrated regularly to ensure that the machine tool can still maintain high-precision processing capacity after long-term use.

IV. Other maintenance points

In addition to the above aspects of maintenance, there are some other matters to pay attention to.

First of all, the working environment of the CNC milling machine should be kept clean and tidy. Avoid dust, debris, etc. entering the machine tool, which has an impact on the accuracy and performance of the machine tool.

Secondly, the operator should operate in strict accordance with the operating procedures to avoid damage to the machine tool caused by misoperation. At the same time, it is necessary to strengthen the training of operators and improve their operational skills and maintenance awareness.

In addition, it is necessary to establish perfect maintenance records and files. Record the content, time, personnel and other information of each maintenance in detail for traceability and analysis. Through the analysis of maintenance records, problems and hidden dangers of machine tools can be found in time and corresponding measures can be taken to solve them.

In a word, the maintenance of CNC milling machines is a systematic and meticulous work, which requires the joint efforts of operators and maintenance personnel. Through the correct maintenance method, the service life of the CNC milling machine can be extended, its processing accuracy and efficiency can be improved, and the production and development of enterprises can be provided with strong support. In the process of maintenance, the operation should be carried out in strict accordance with the requirements and specifications of the manufacturer to ensure the effectiveness and safety of the maintenance work. At the same time, we should constantly learn and master new maintenance technologies and methods, constantly improve the maintenance level, and escort the efficient operation of CNC milling machines.

Millingmachine@tajane.com This is my email address. If you need it, you can email me. I’m waiting for your letter in China.