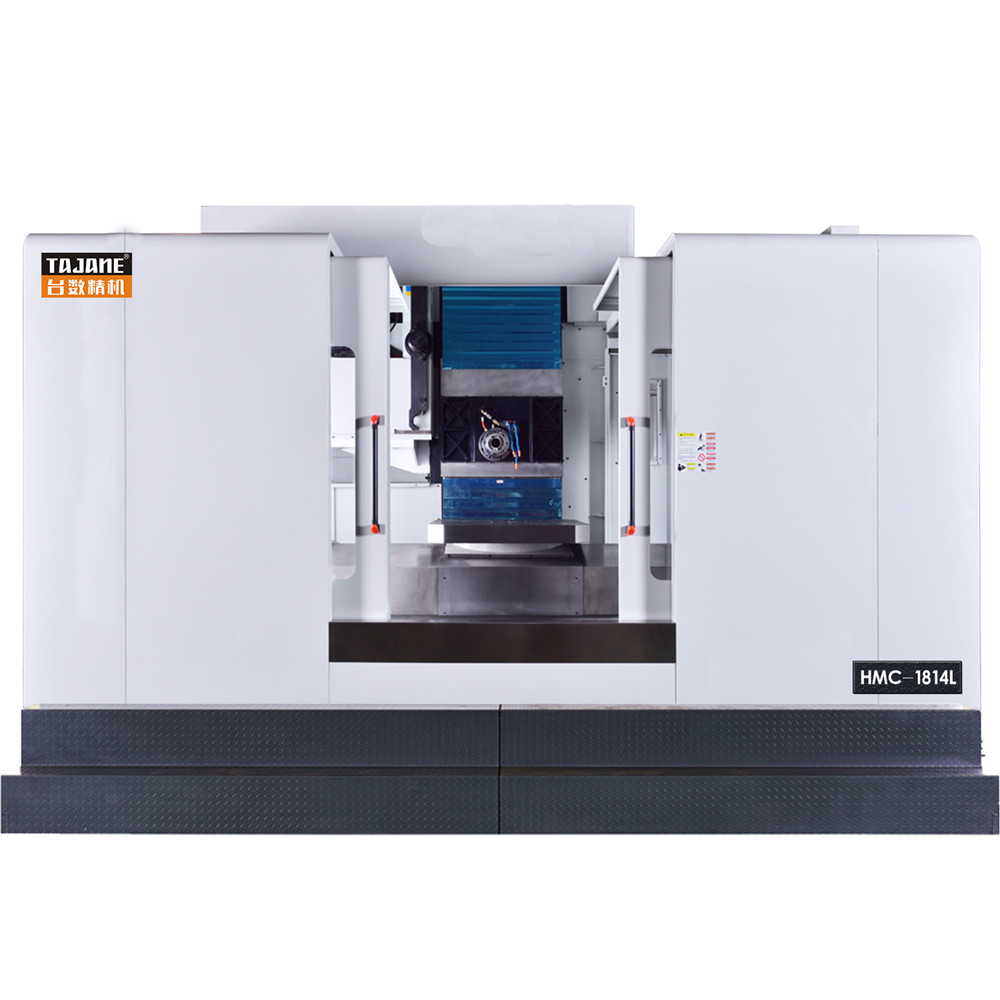

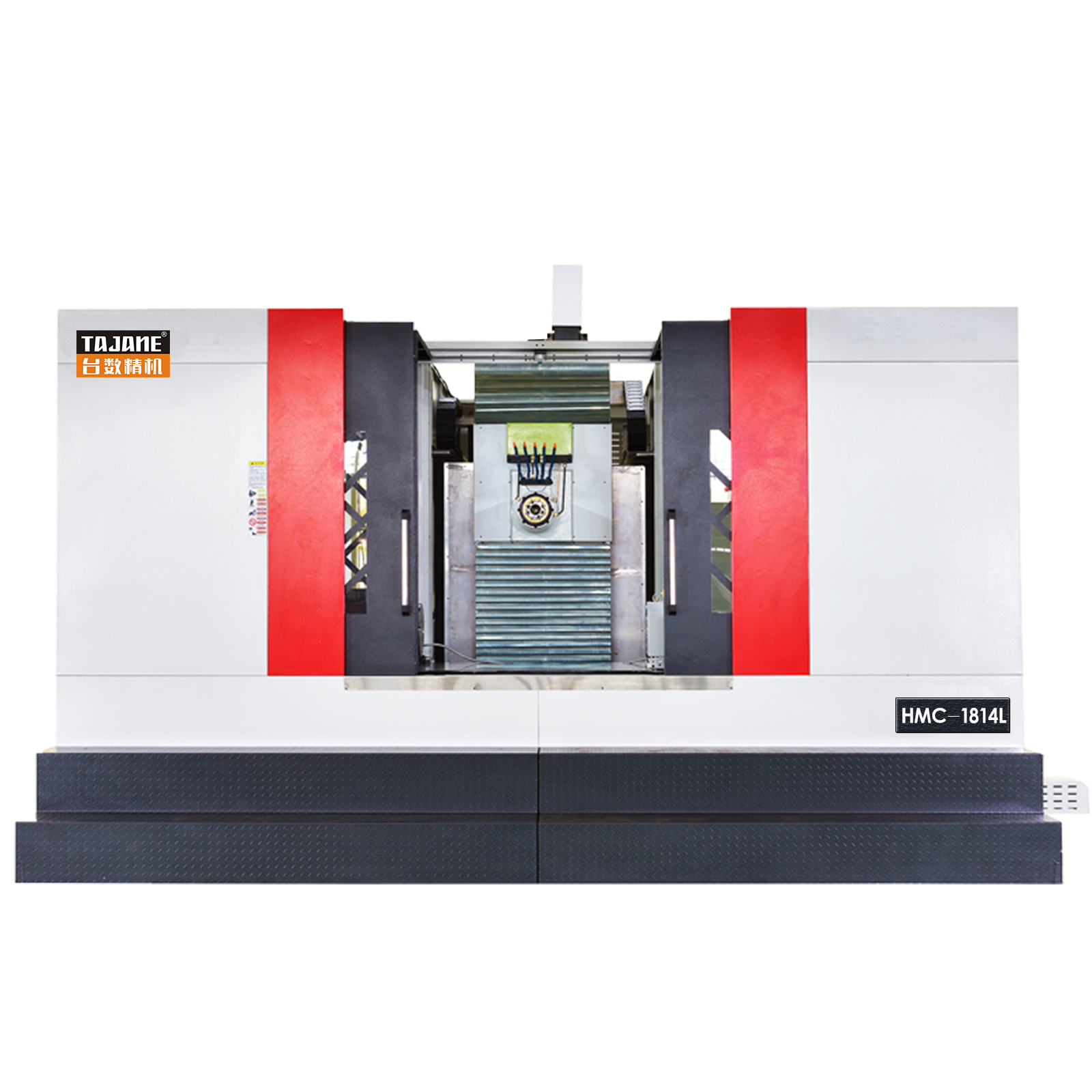

Horizontal Machining Center HMC-1814L

Qingdao Taizheng vertical machining center is your ideal choice for precision machining. Our TAJANE vertical machining center series is specially designed for processing complex parts such as plates, plates, molds and small shells. Vertical machining centers perfectly perform operations such as milling, boring, drilling, tapping and thread cutting.

The unique advantages of our products are high precision and fast processing speed. Through advanced technology and careful design, the machining centers we offer can complete the processing needs of any complex parts with excellent precision. Whether it is tiny details or complex shapes, our products can be perfectly restored and ensure that every step of processing is accurate.

Product use

The vertical machining center is an efficient and precise processing equipment that is widely used in parts processing in various fields. It can not only be used to process precision parts of 5G products, but can also meet the processing needs of shell parts, automotive parts and various mold parts. Especially when it comes to batch machining, vertical machining centers excel, enabling efficient, high-precision machining. In addition, this equipment can also realize high-speed processing of box parts, improving processing efficiency and processing accuracy. In short, the vertical machining center is a very excellent processing equipment that provides excellent solutions for parts processing in various fields.

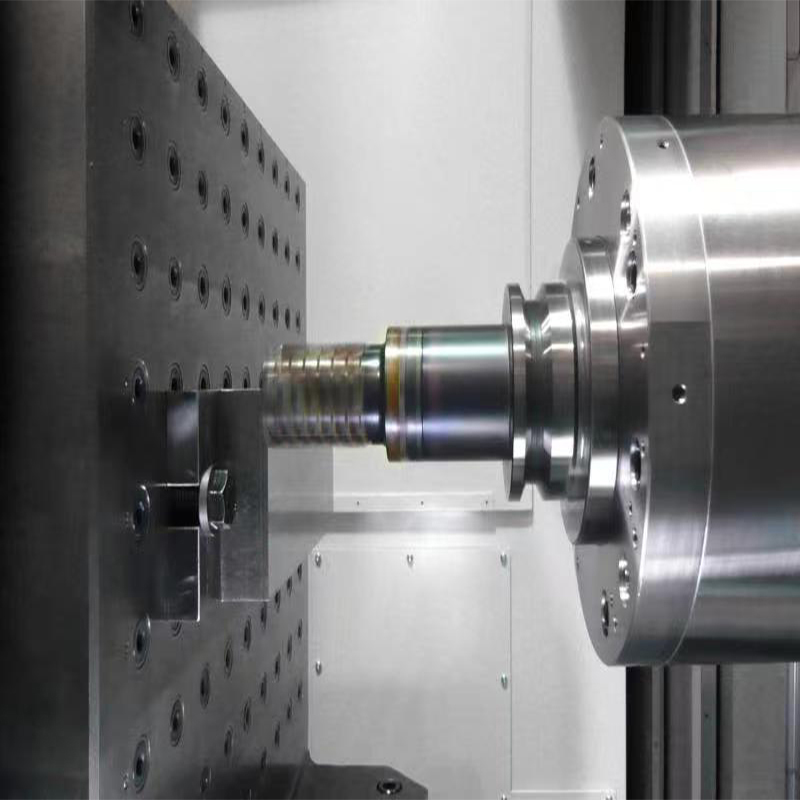

Horizontal machining center, widely used in automotive, aerospace, general machinery and other industries

Horizontal machining center. Most suitable for processing large strokes and complex precision parts

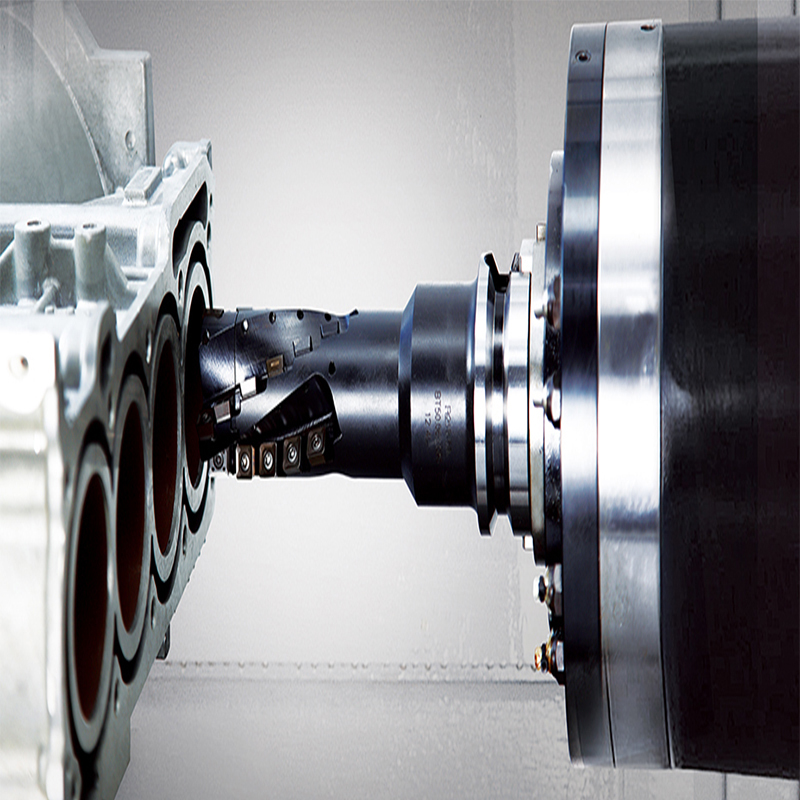

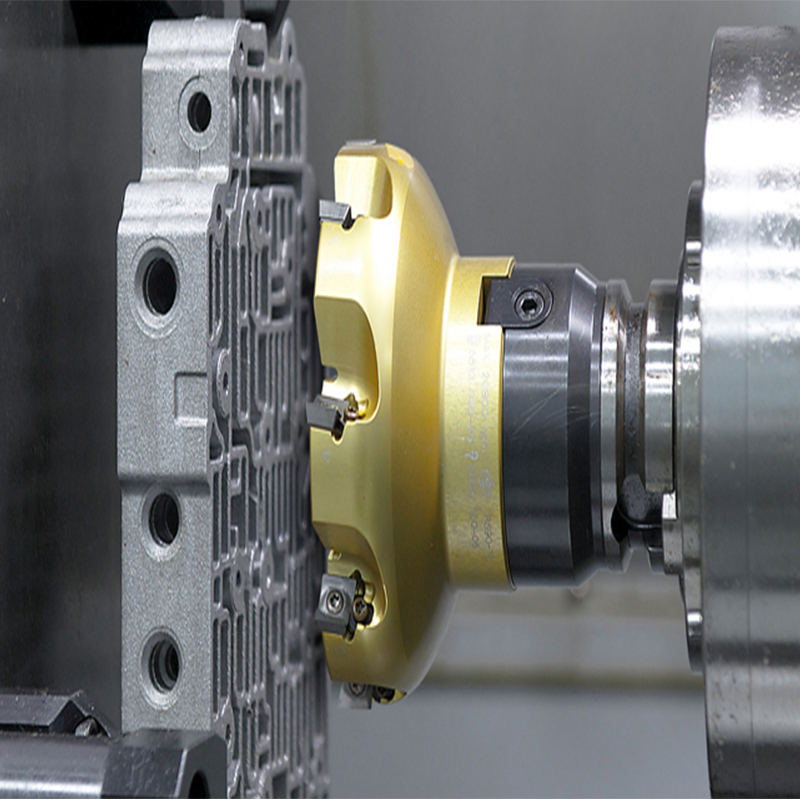

Horizontal machining center, suitable for multi-working surface and multi-process processing of parts

Horizontal machining centers are widely used in complex parts. Surface and hole processing.

Horizontal machining centers are widely used in complex parts. Surface and hole processing.

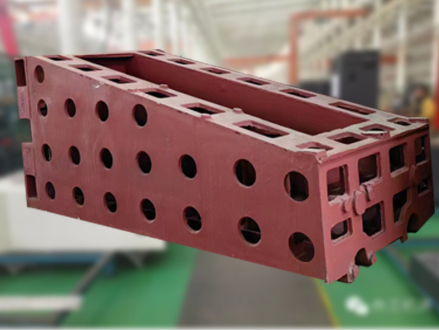

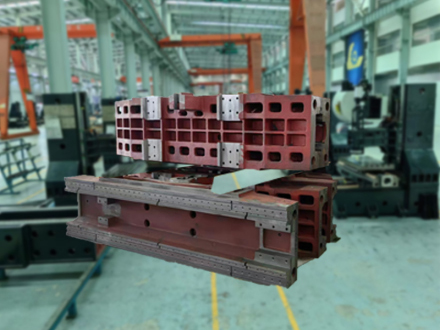

Product casting process

The castings of CNC VMC-855 vertical machining center adopt Meehanner casting process, grade TH300, which has high strength and high wear resistance. The machining center adopts a double-wall grid-like rib structure inside the casting, and the spindle box adopts an optimized design and reasonable layout, which can provide higher machining accuracy and efficiency. In addition, the natural failure design of the bed and column effectively improves the accuracy of the machining center. The worktable cross slide and base meet the needs of heavy cutting and rapid movement, providing users with a more efficient and stable processing experience.

CNC Horizontal machining center, the casting adopts Meehanite casting process, and the label is TH300.

Horizontal milling machine, table cross slide and base, to meet heavy cutting and rapid movement

Horizontal milling machine, the inner part of the casting adopts double-walled grid-shaped rib structure.

Horizontal milling machine, the bed and columns fail naturally, improving the precision of the machining center.

Horizontal machining center, optimized design for five major castings, reasonable layout

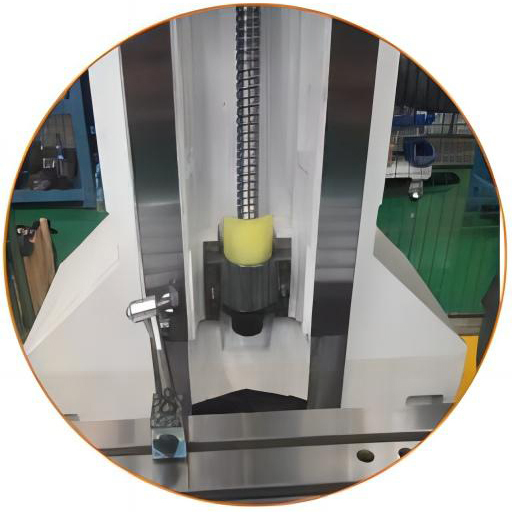

Boutique Parts

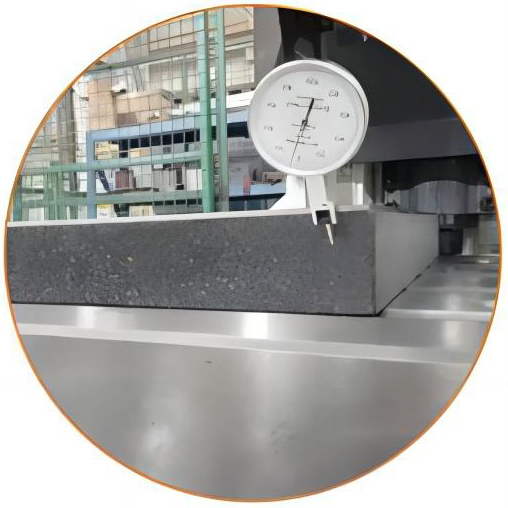

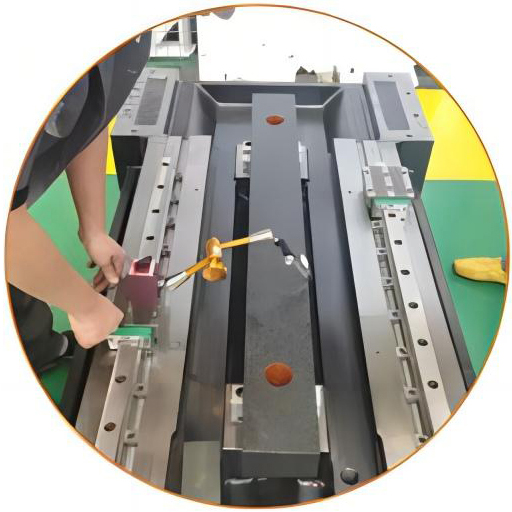

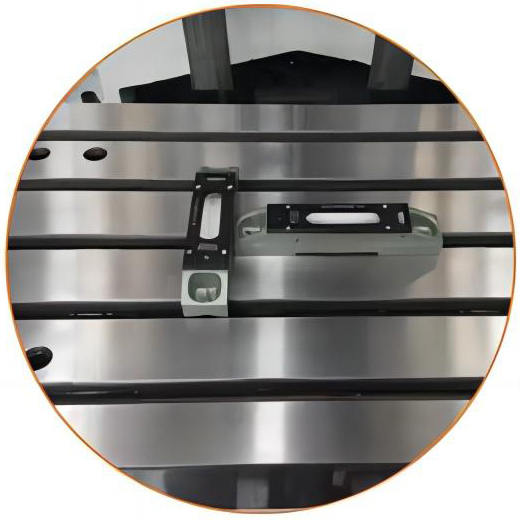

Precision assembly inspection control process

Workbench Accuracy Test

Opto-Mechanical Component Inspection

Verticality Detection

Parallelism Detection

Nut Seat Accuracy Inspection

Angle Deviation Detection

Configure brand CNC system

TAJANE Horizontal machining center machine tools, according to customer needs, provide various brands of CNC systems to meet customers' different needs for vertical machining centers, FANUC, SIEMENS, MITSUBISH, SYNTEC。

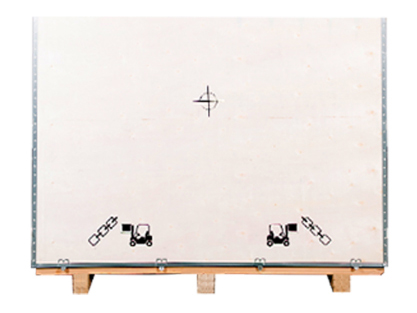

Fully enclosed packaging, escort for transportation

Fully enclosed wooden packaging

Horizontal Machining Center HMC-1814L, fully enclosed package, escort for transportation

Vacuum packaging in the box

Horizontal Machining Center HMC-1814L, with moisture-proof vacuum packaging inside the box, suitable for long-distance long-distance transportation

Clear mark

Horizontal Machining Center HMC-1814L, with clear markings in the packing box, loading and unloading icons, model weight and size, and high recognition

Solid wood bottom bracket

Horizontal Machining Center HMC-1814L, the bottom of the packing box is made of solid wood, which is hard and non-slip, and fastens to lock the goods

| Specifications | HMC-1814L | |||

| Travel | X-Axis,Y-Axis,Z-Axis | X: 1050, Y: 850, Z: 950mm | ||

| Spindle Nose To Pallet | 150-1100mm | |||

| Spindle Center To Pallet Surface | 90-940mm | |||

| Table | Table Size | 630X630mm | ||

| Workbench Number | 1(OP:2) | |||

| Workbench Surface Configuration | M16-125mm | |||

| The Workbench Maximum Load | 1200kg | |||

| The Smallest Unit of Setting | 1°(OP:0.001°) | |||

| Controller and Motor | 0IMF-ß | 0IMF-α | 0IMF-ß | |

| Spindle Motor | 15/18.5 kW (143.3Nm) | 22/26 kW (140Nm) | 15/18.5 kW (143.3Nm) | |

| X Axis Servo Motor | 3kW(36Nm) | 7kW(30Nm) | 3kW(36Nm) | |

| Y Axis Servo Motor | 3kW(36Nm)BS | 6kW(38Nm)BS | 3kW(36Nm)BS | |

| Z Axis Servo Motor | 3kW(36Nm) | 7kW(30Nm) | 3kW(36Nm) | |

| B Axis Servo Motor | 2.5kW (20Nm) | 3kW (12Nm) | 2.5kW (20Nm) | |

| Feed Rate | 0IMF-ß | 0IMF-α | 0IMF-ß | |

| X. Z Axis Rapid Feed Rate | 24m/min | 24m/min | 24m/min | |

| Y Axis Rapid Feed Rate | 24m/min | 24m/min | 24m/min | |

| X. Y. Z Max.Cutting Feed Rate | 6m/min | 6m/min | 6m/min | |

| ATC | Arm Type (Tool to Tool) | 30T (4.5 sec) | ||

| Tool Shank | BT-50 | |||

| Max. Tool Diameter*Length(adjacent) | φ200*350mm(φ105*350mm) | |||

| Max. Tool Weight | 15kg | |||

| Machine Accuracy | Positioning Accuracy (JIS) | ± 0.005mm / 300mm | ||

| Repeat Poitioning Accuracy (JIS) | ± 0.003mm | |||

| Others | Approximate Weight | A: 15500kg / B: 17000kg | ||

| Floor Space Measurement | A: 6000*4600*3800mm B: 6500*4600*3800mm | |||

Standard Accessories

● Spindle and servo motor load display

●Spindle and servo overload protection

●Rigid tapping

● Fully enclosed protective cover

● Electronic handwheel

● lighting fixtures

●Double spiral chip conveyor

●Automatic lubrication system

●Electrical box thermostat

●Spindle tool cooling system

●RS232 interface

●Airsoft guns

●Spindle taper cleaner

●Toolbox

Optional Accessories

●Three-axis grating ruler detection device

●Workpiece measuring system

●Tool measuring system

●Spindle internal cooling

●CNC rotary table

●Chain chip conveyor

●Tool length setter and edge finder

●Water separator

●Spindle water cooling device

●Internet function