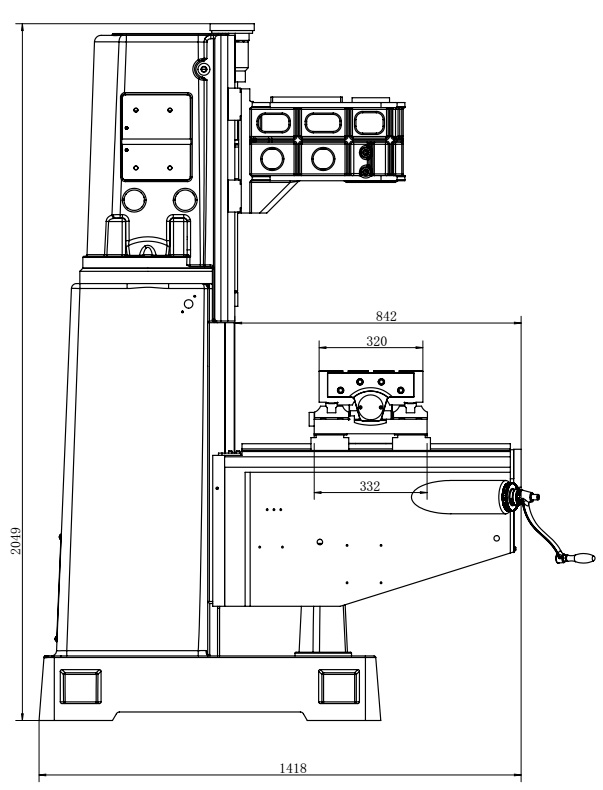

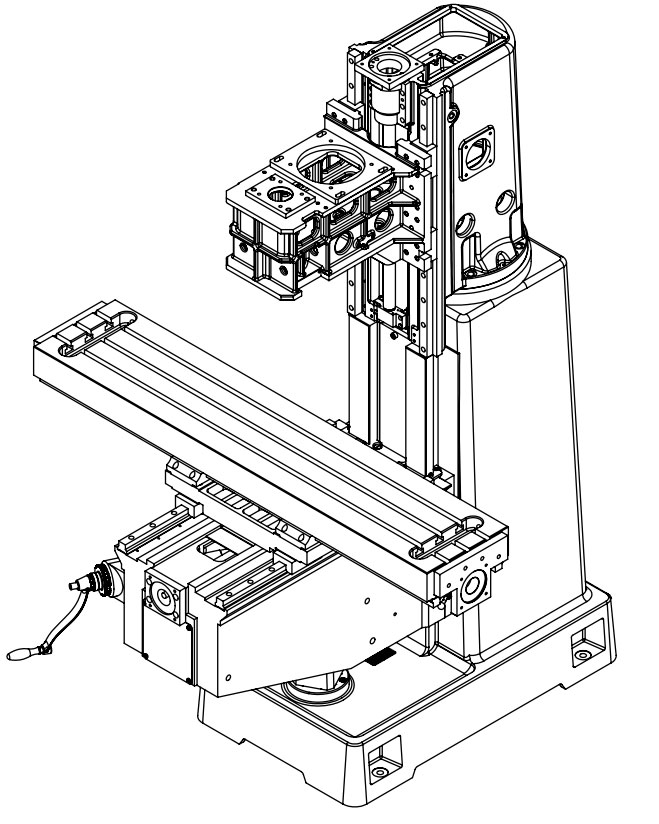

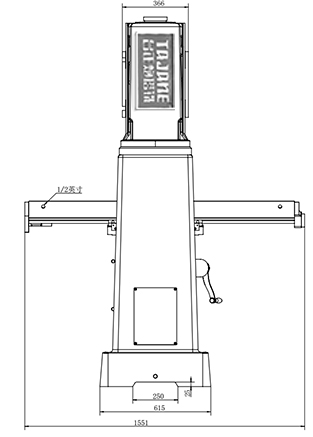

CNC MILLING MACHINE MX-5SH

Bare Machine Design Drawings Optomechanical design

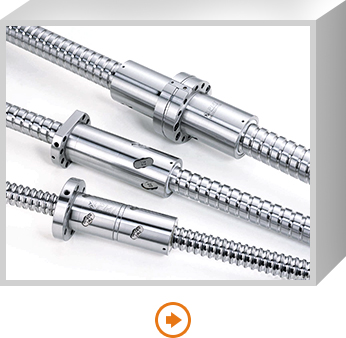

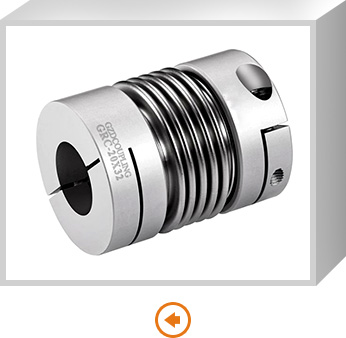

World-class precision components

Mihanna Casting Technology

Ball screw Linear slide rail

Spindle made by KENTURN

HERG Lubrication Pump

Pull rod Locking machine

Coupling made by NBK Japan

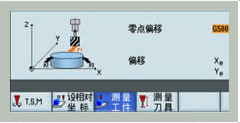

Numerical control system SIMMENS 808D

HDW Tool magazine

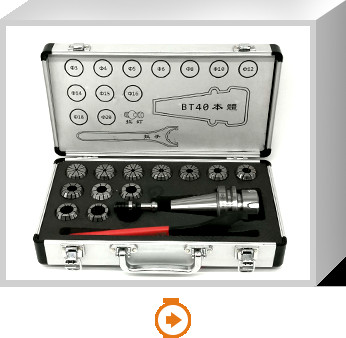

High precision chuck assembly

Milling machine accessories meet different processing needs

15pic BT40 Chuck combination

►φ03/4/5/6/8

►φ10/12/14/15

►16/18/20

100pic drilling bit

► Different size

► Suitable for punching

QM-160 Precise Flat nose pliers

►Super clamping force

►Precision and durability

►Famous brand

58 Precision combination pressure plate suit

►Super clamping force

►Precision persistence

►German quality

Edge finder

►Quick and convenient

►Finding Edge easy

Environmental protection Protection cover

► Protecting workers'safety

► Protect the environment

►Beautiful

Integral drill chuck

► Integral

► Automatic locking

► Size :Φ O.5~16mm

Machine tool isolator

► Super Supporting Force

► Stable shock absorption

► Durable

Cooling system

► Delay cutter life

► Oil chip separation

► Large water yield

PRESENT NINE CONSUMABLES TO SOLVE YOUR WORRIES

Present nine consumables to solve your worries

1.Pull nail 7pic

2.Floodlight 1set

3.Chip retaining rubber 1set

4.Locking handle 1pic

5.Handheld adjuster 1set

6.Unlock Tool Button 1pic

7.Outlet pipe 1pic

8.Synchronous belt 1pic

9.Hydraulic oil 1 barrels

Electrical safety

Feed shaft Spindle tool Rate adjustment knob

Graphic programming Colour display screen

Multilingual Interface

Shortcut button

Graphic programming

Multiplying knob

International brand

packing

Steel belt fastener Wood packaging ,

Locking connection Firm tensile strength.

Free transportation in China

Undertaking transportation insurance.

Perfect after-sales service

Mechanical Parts and Electrical Appliances

Guaranteed for 12 Months

| Bed dimension | 1473 x 320mm |

| X axis of worktable stroke | 950mm/980mm(limit stroke) |

| Sliding saddle stroke (Y axis) | 380mm/400mm(limit stroke) |

| Spindle box stroke (Z axis) | 415mm |

| Elevator manual stroke | 380mm |

| Table load bearing | 280KGBall wire track(Full strokeBall wire track)/350KG(Middle of the working table400mm) |

| T-slot size | 3 x 16 x 75mm |

| Principal axis | BT40- Ball wire track∅120 Taiwan Keychun |

| Main shaft speed | 8000rpm |

| Spindle power | 3.75KWBall wire track(RatedBall wire track) 5.5KWBall wire track(OverloadBall wire track) |

| voltage | 380V |

| frequency | 50/60 |

| Positioning accuracy / repeat positioning accuracy | Middle of the working table400mm:0.009mm/Ball wire track±0.003mm |

| Full stroke950mm:0.02mmBall wire track、arbitrary300mm/0.009mm | |

| Feed motor power | XBall wire track、Y/7Nm Z/15Nm with brake |

| Fastest moving speed | XBall wire track、Y axis/12m/min Z axis/18m/min |

| Ball wire rod type X shaft | 3208 Taiwan original |

| Ball wire rod type Y shaft | 3208 Taiwan original |

| Ball wire rod model Z shaft | 3205 Taiwan original |

| Rail X axis | 35Ball wire track wholly owned by Taiwan |

| Line rail Y axis | 35Ball wire track wholly owned by Taiwan |

| Rail Z axis | 30Ball wire track wholly owned by Taiwan |

| clutch | NBKJapanese |

| Knife cylinder | Haocheng Taiwan |

| tool magazine | 12 bucket type Taiwan brand |

| system | Siemens, Germany808D system |

| Machine tool shape dimension | 2000x1920x2500 |

| weight | 2600kg |

| Positioning accuracy X-directional full stroke / repeat positioning accuracy | 0.02mm/0.012mm |

| Positioning accuracy / repeat location of 400mm in the middle of workbench | 0.009mm/0.006mm |

Accessories

One piece of precision edge finder

QH160 precision flat pliers

58-piece set of M12 combined pressure plate

15-piece set of high-precision BT40 chuck set

A set of high-precision BT40 powerful integrated drill chuck

A set of environmentally friendly protective covers

Random wearing parts (gift)

Anti-peeling set

A set of handle pull studs

Two locking handles for workbench

A barrel of special hydraulic oil for the knife cylinder

Special accessories

Grating ruler

chipper

CNC rotary table